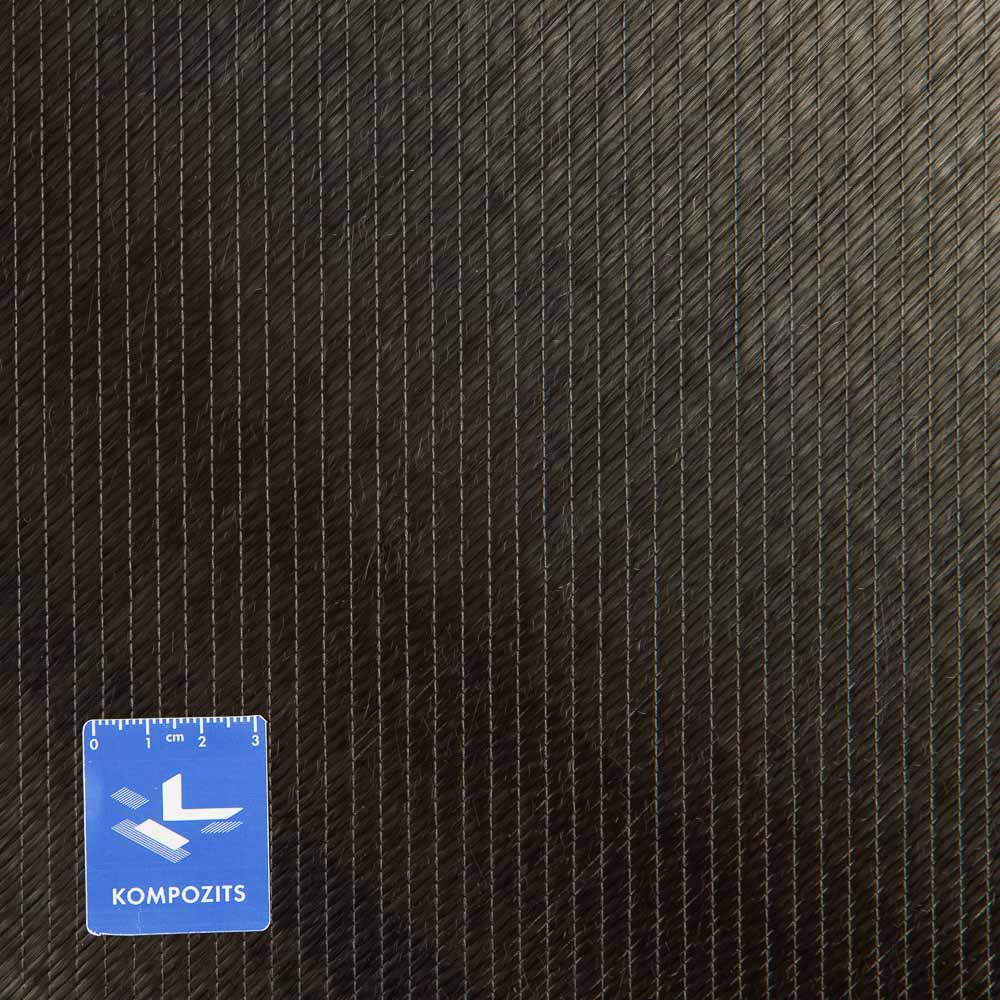

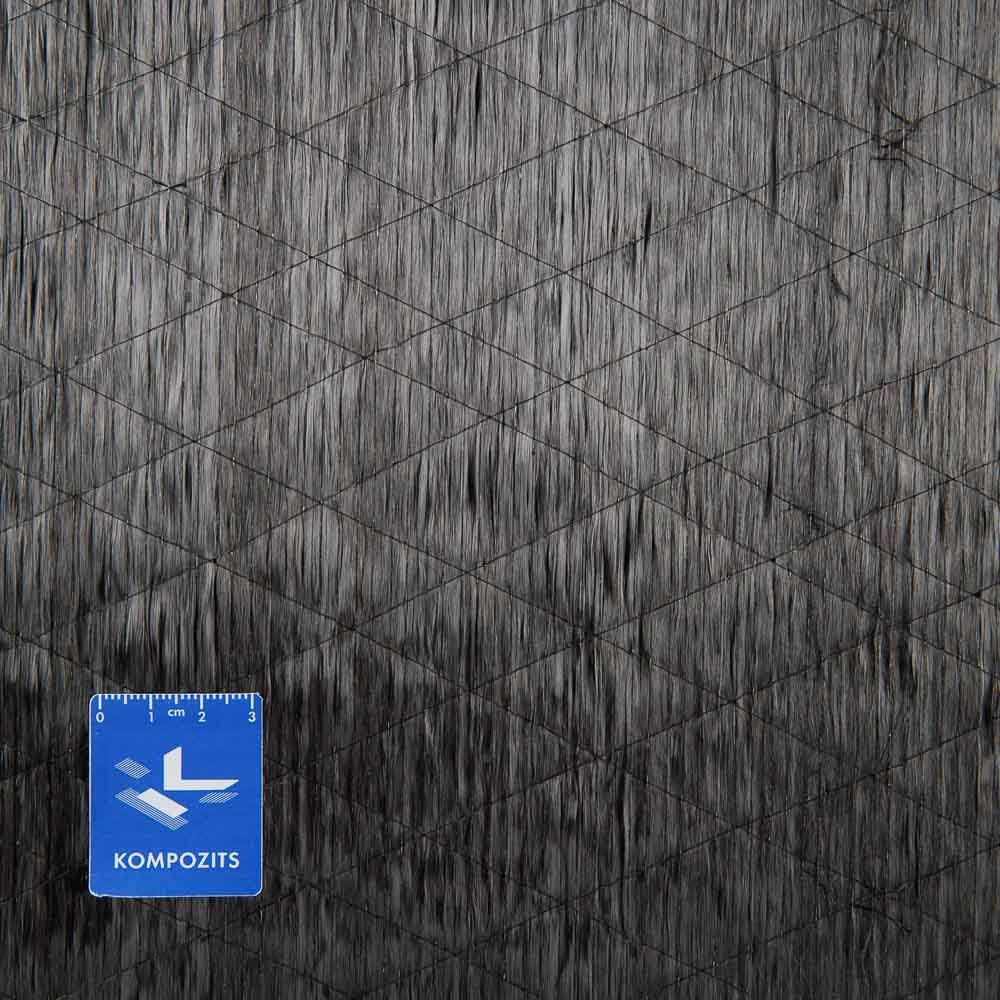

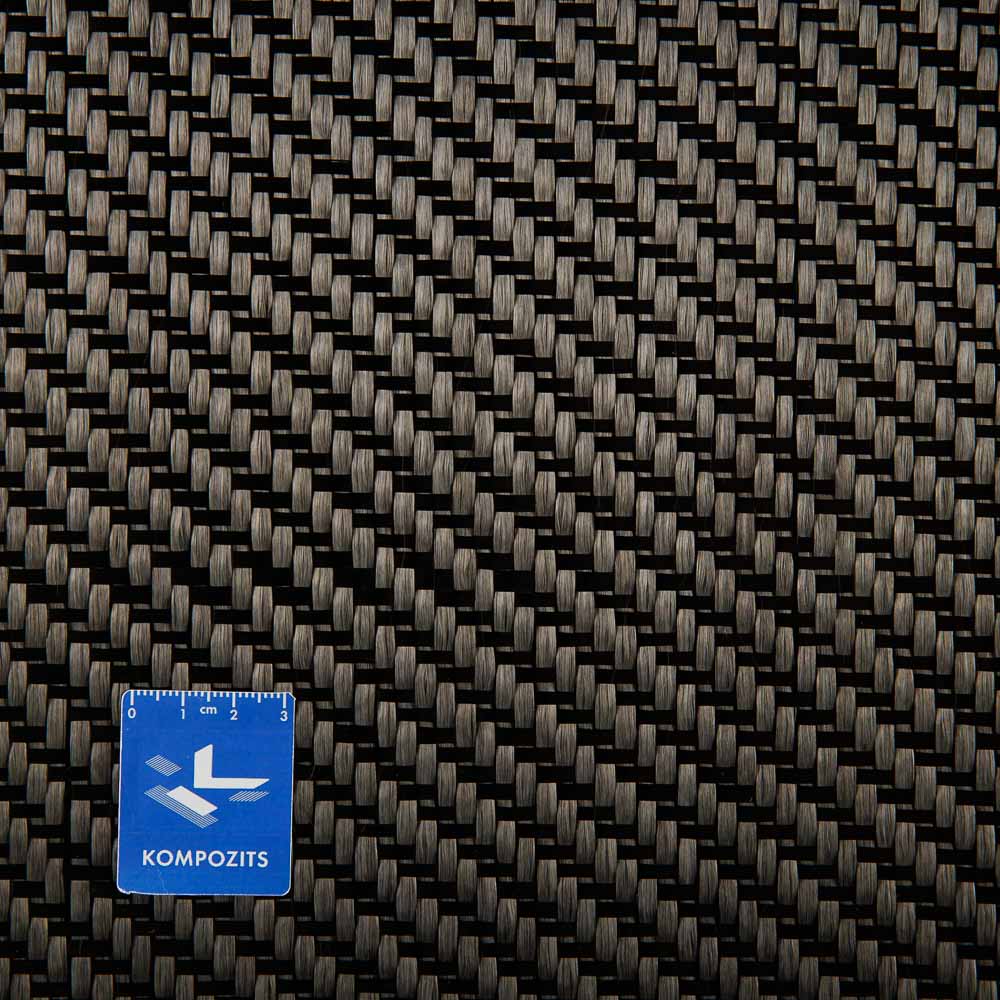

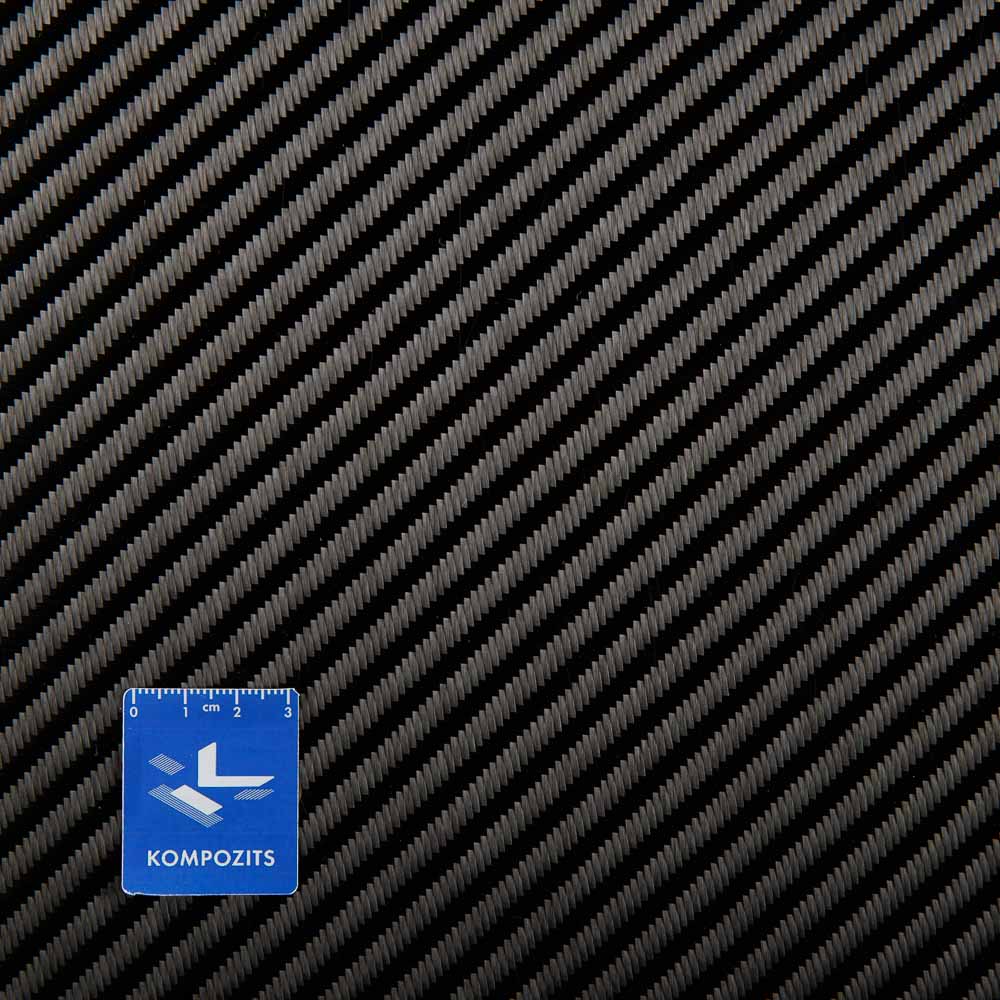

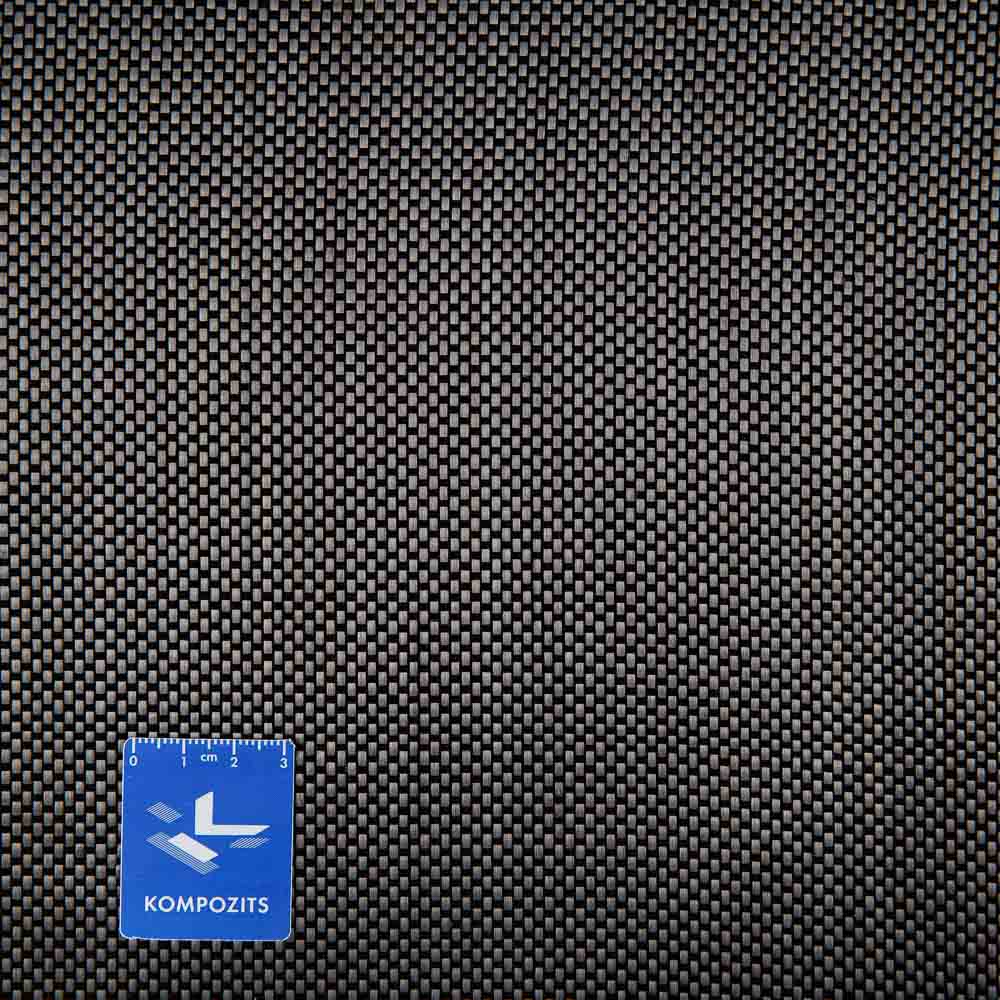

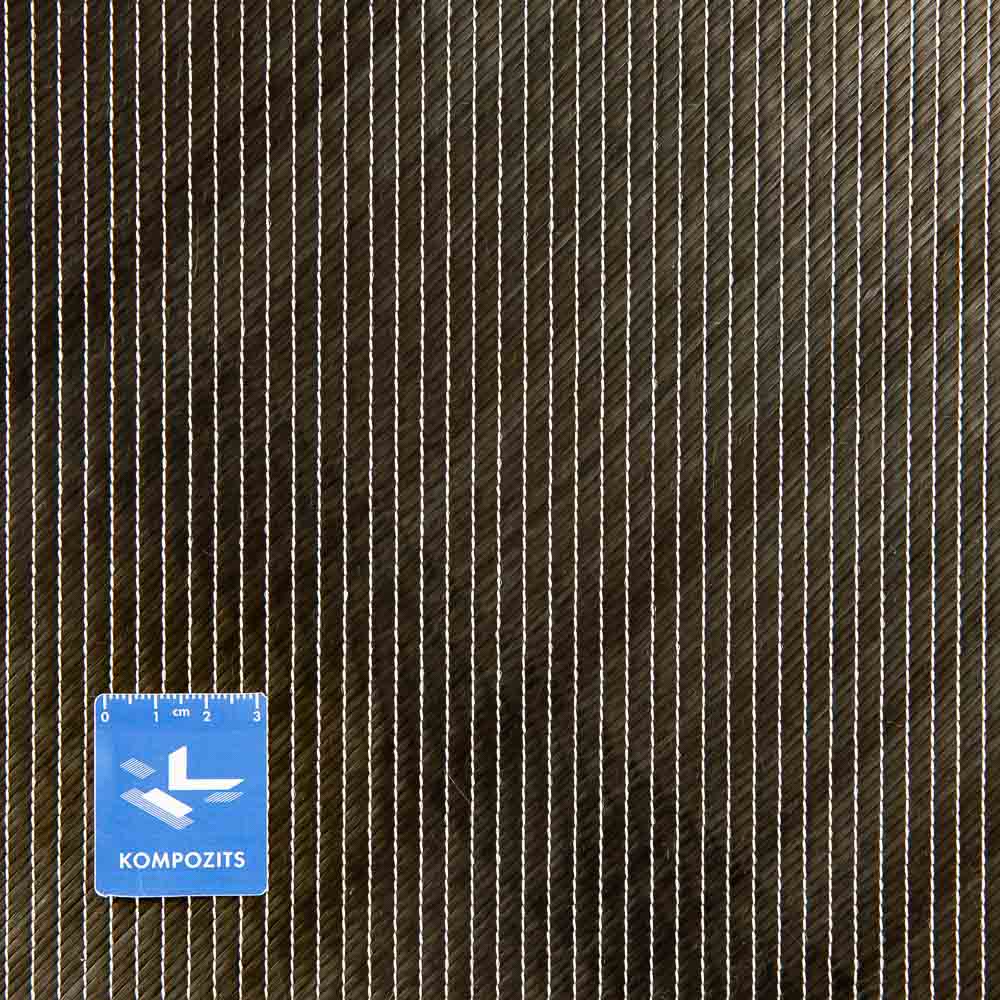

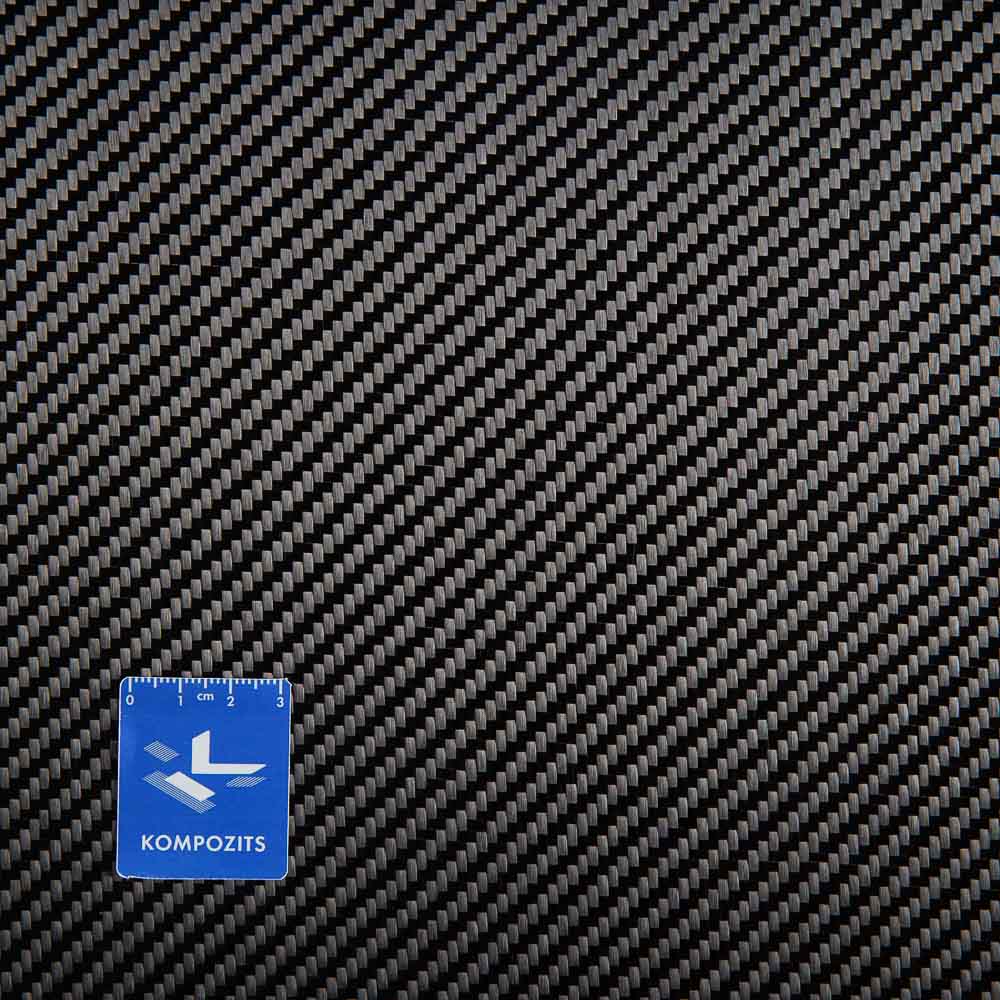

Biaxial carbon fabric 150 g/m2 (+/-45) is a high quality material derived from carbon fibre and is used in the manufacture of composite structures such as ships, yachts, aircraft, car/motorcycle parts, sports equipment, etc.

Carbon fabrics are characterised by their high hardness, thermal resistance, low weight and belong to the group of materials that are difficult to burn.

On average, one layer of carbon fibre in a fabric laminate replaces five layers of glass fibre of the same thickness, allowing very light and rigid parts or structures to be made. Most commonly used in vacuum and vacuum infusion technologies, or for hand lamination and part wrapping, using epoxy, urethane, vinylester and polyester resins.

Features:

- High hardness

- Very robust

- Easy

- High chemical resistance

- High temperature tolerance

- Low thermal expansion

| Weight | 150 g/m2 ±5% |

| Roll Width | 127 cm |

| Fabric thickness | 0,21 mm |

| Laminate thickness | 0,24 mm |

| Resin uptake | ~180 g/m2 |

Price is per 1 m2 – 1270×790 mm.