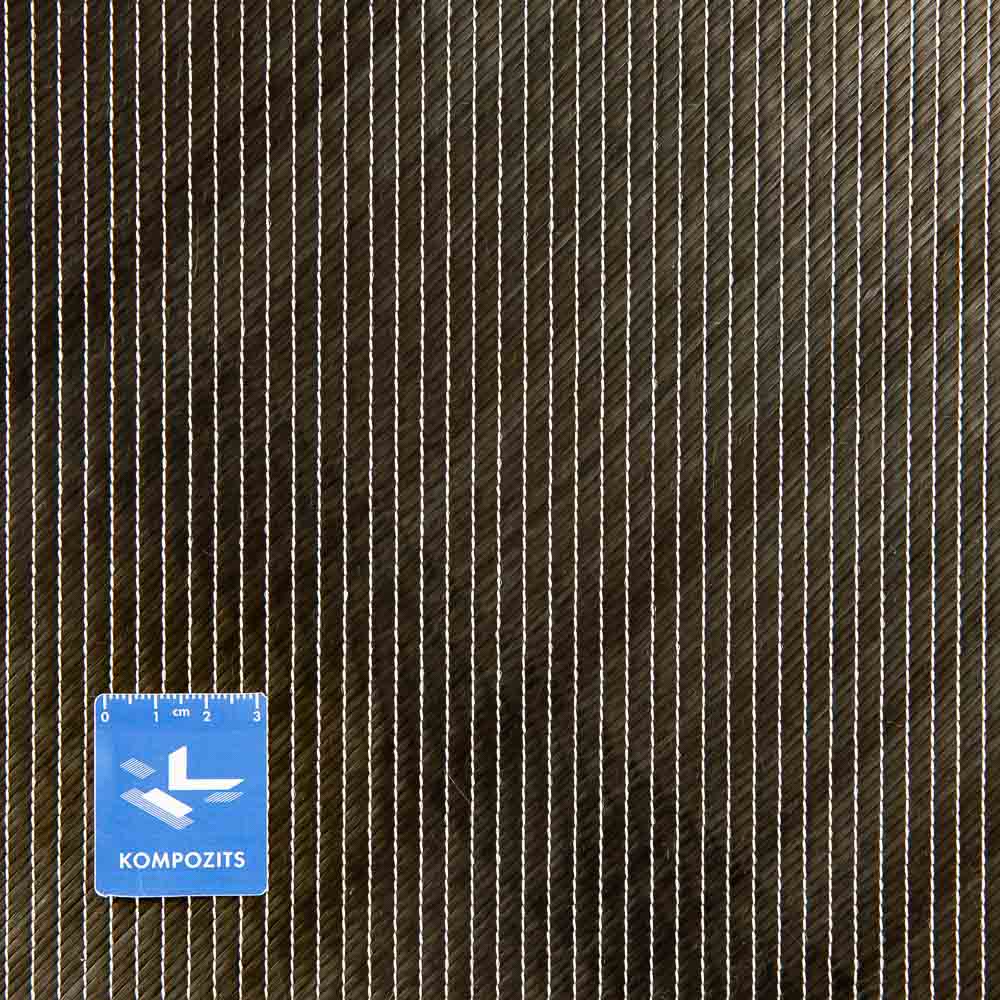

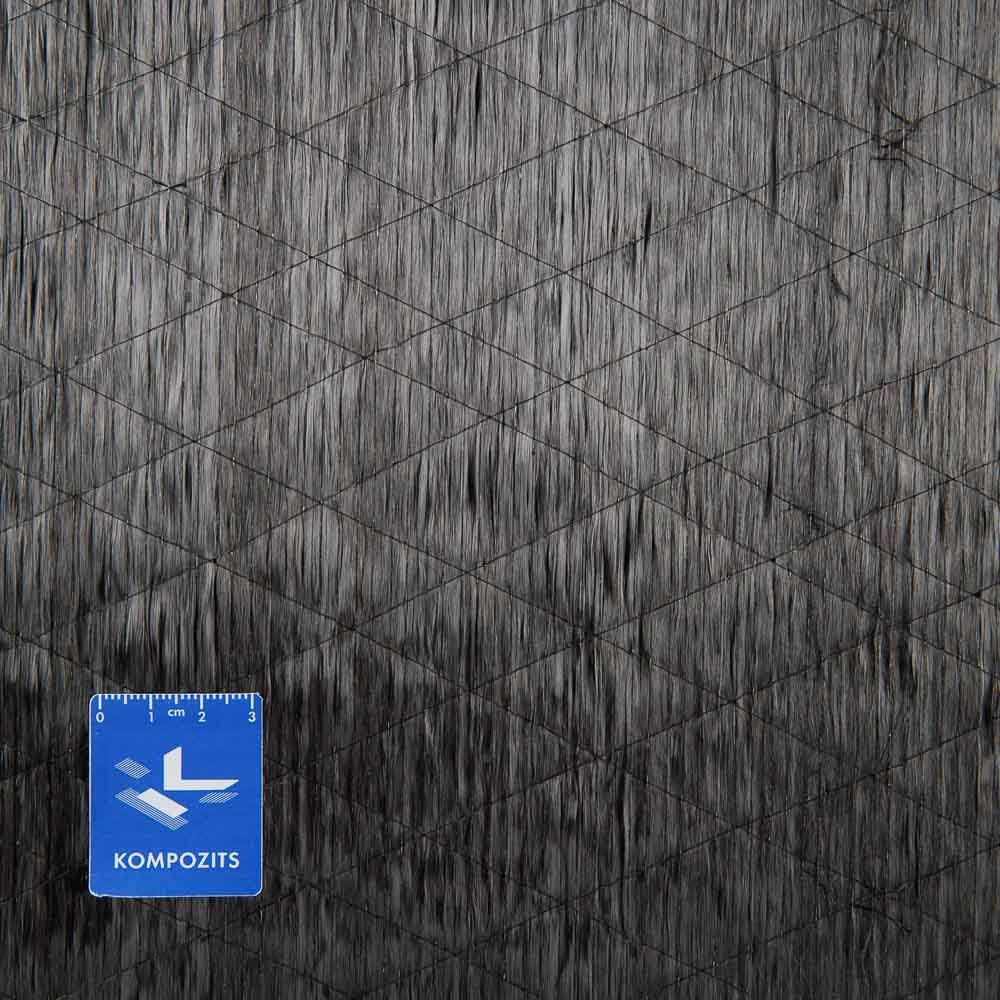

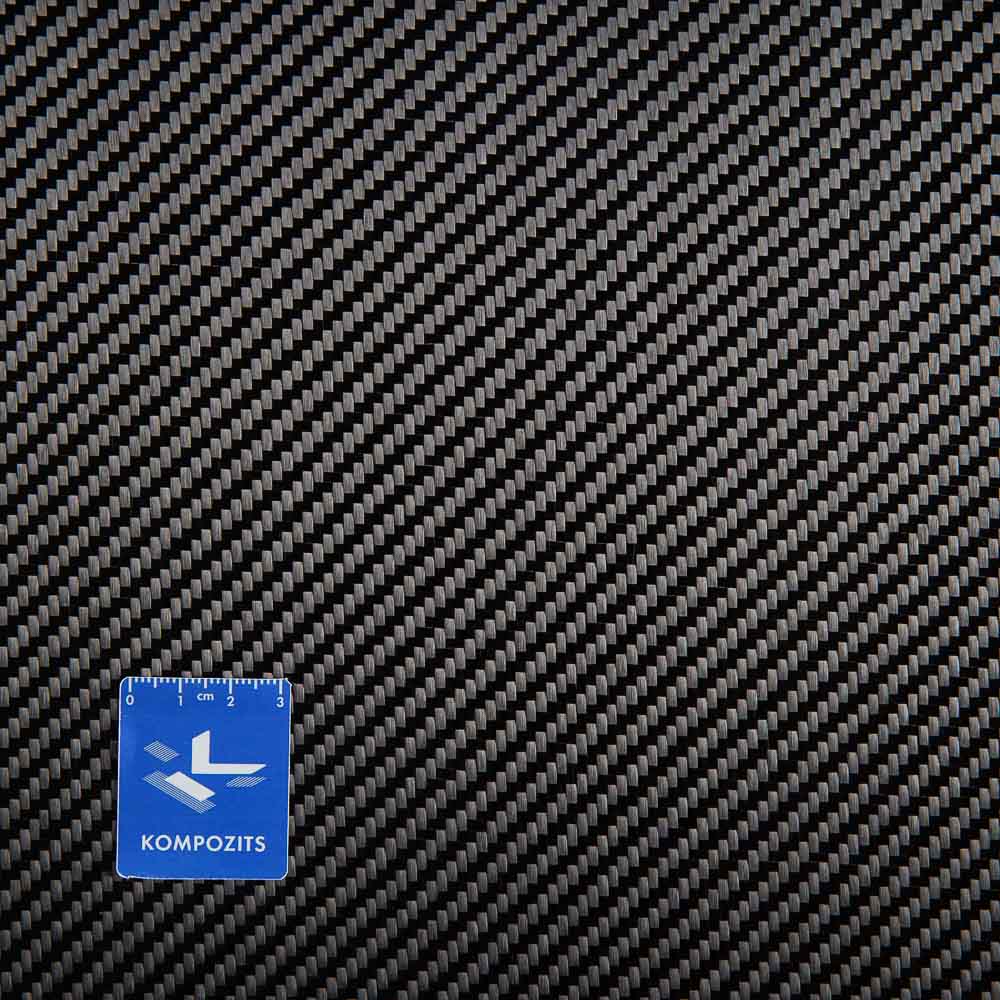

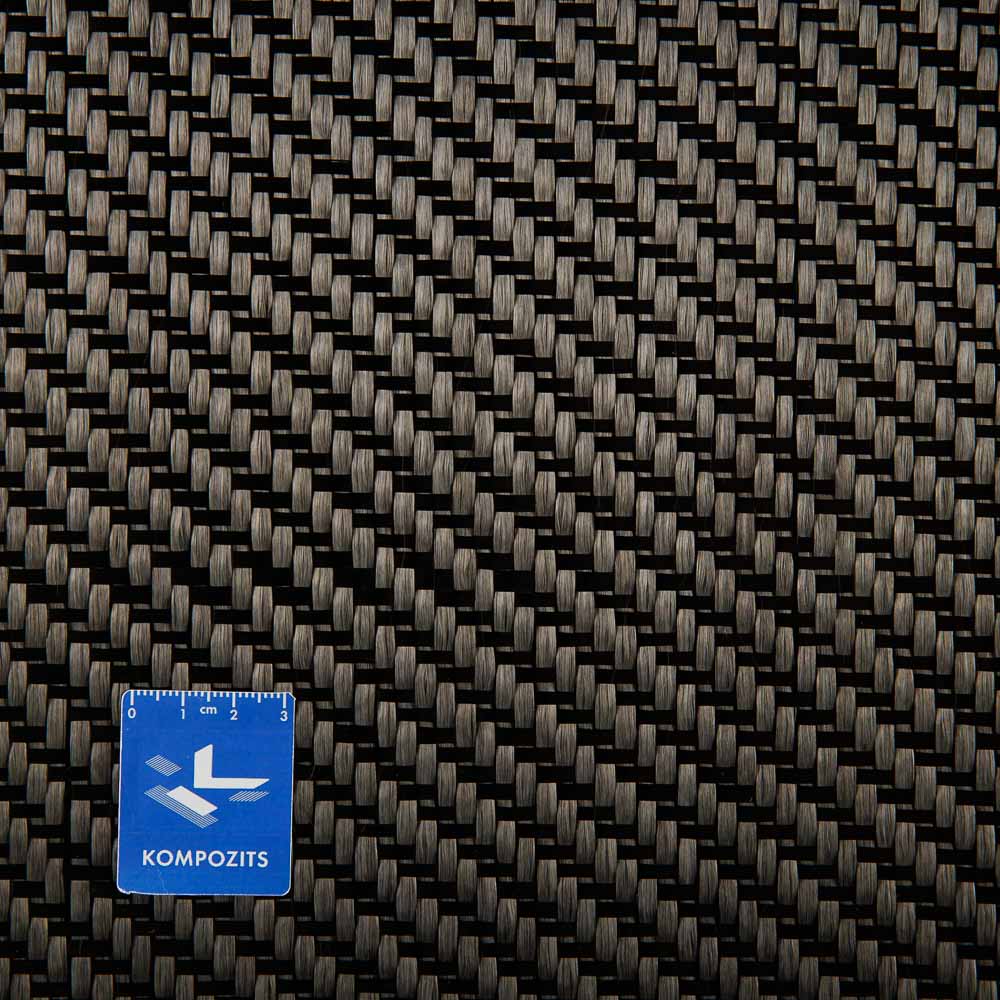

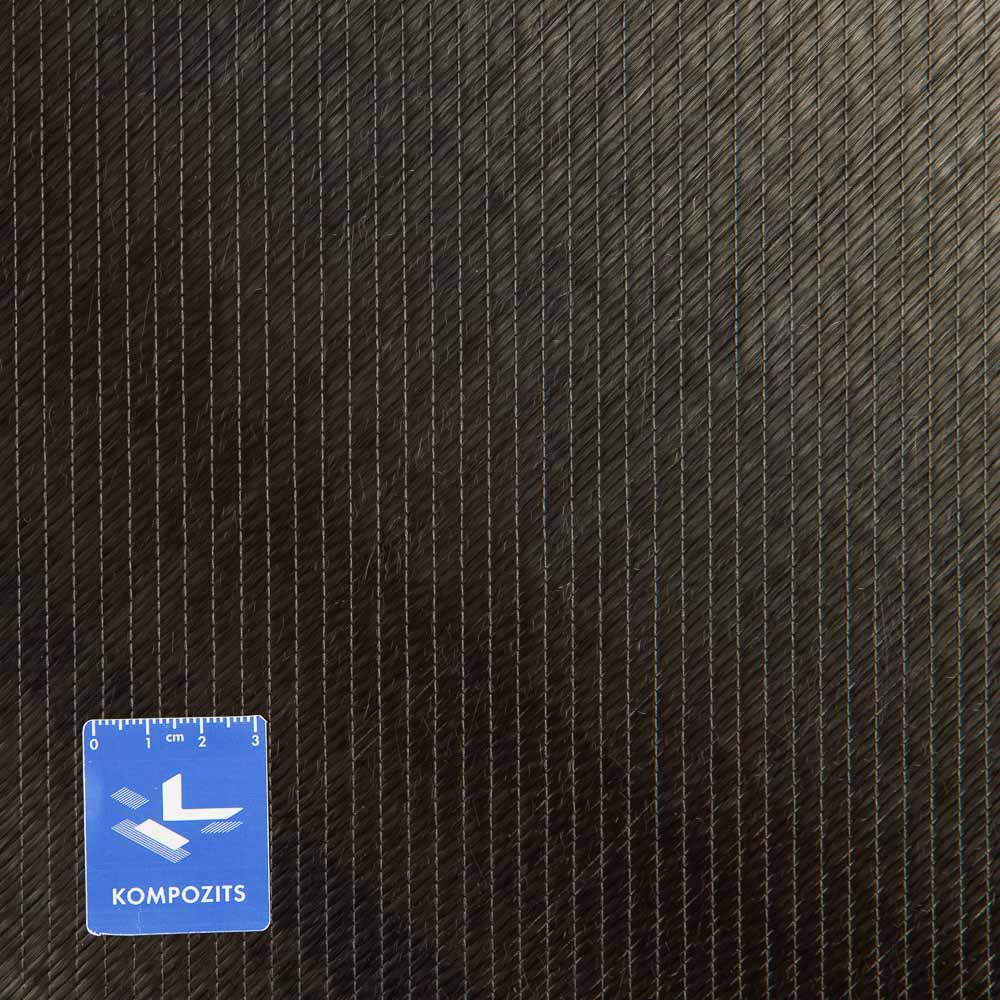

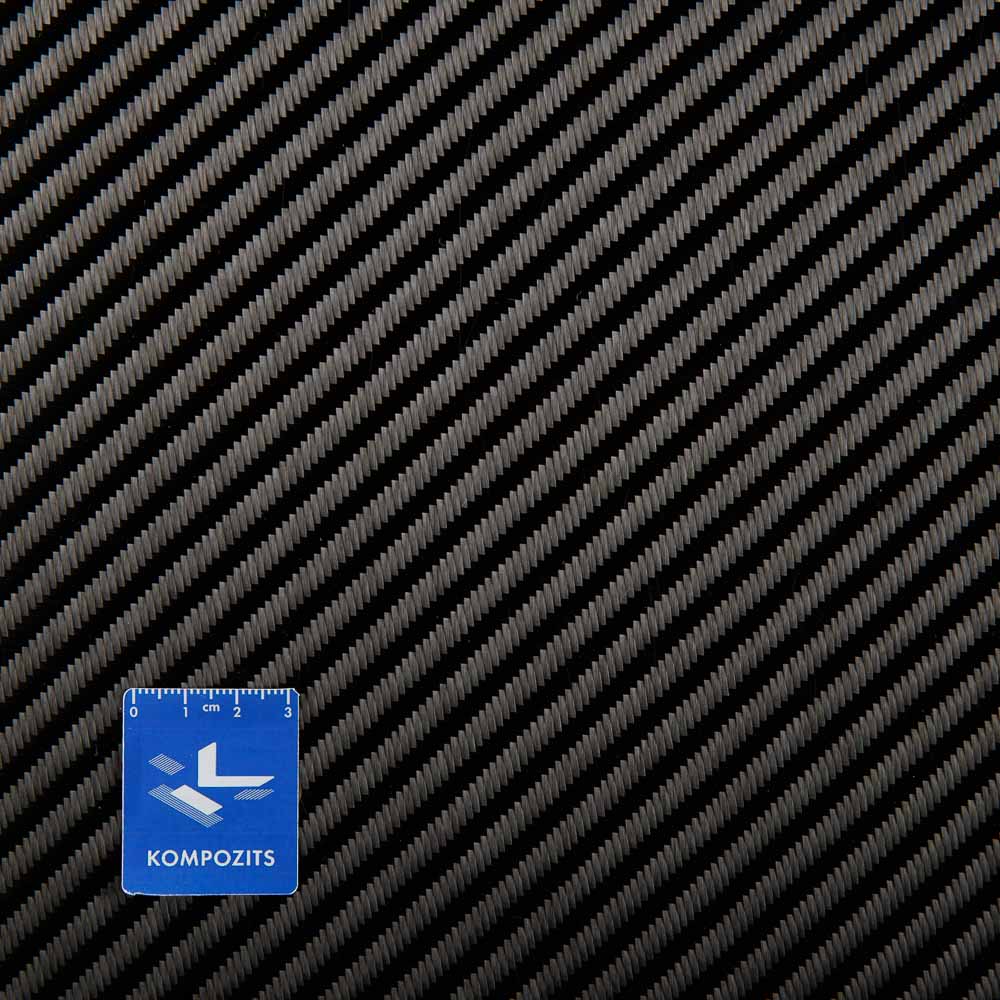

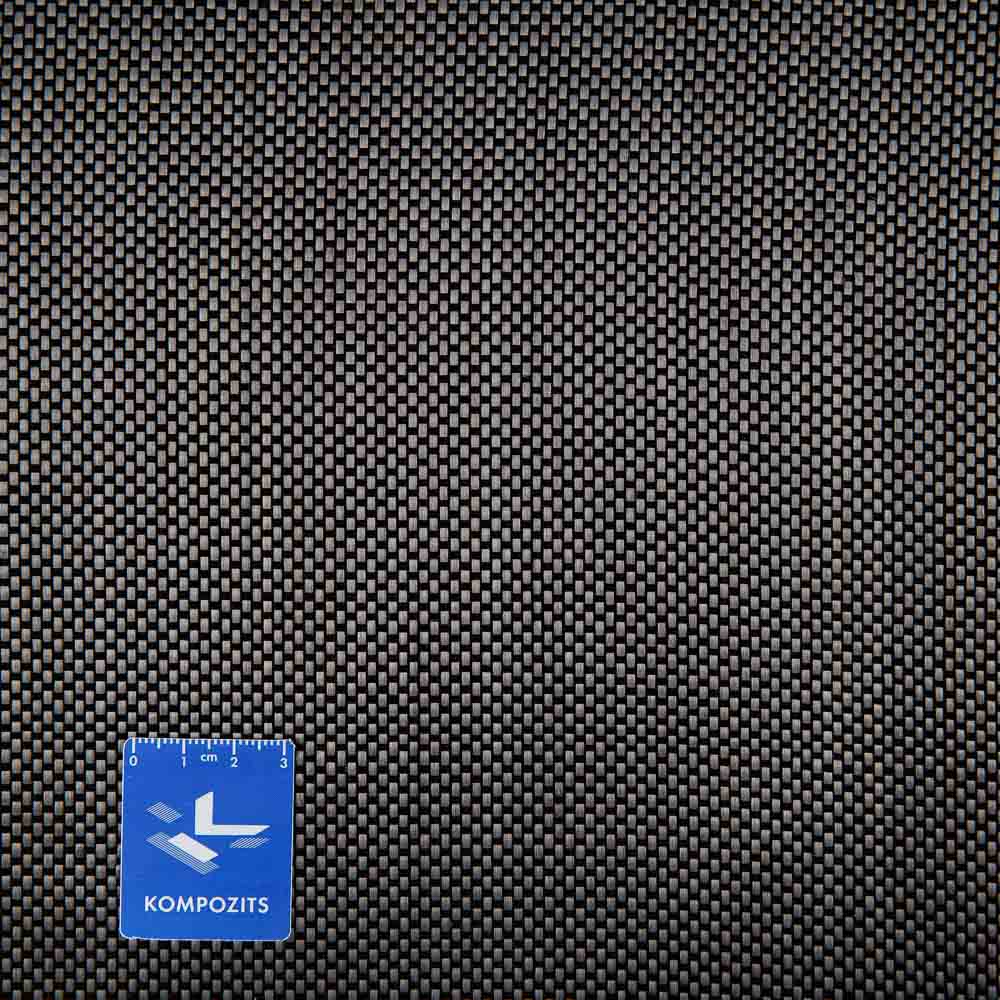

Carbon Fiber Biaxial Fabric is engineered to provide superior strength and durability, ideal for high-performance applications. Woven at a ±45° orientation, this 400 g/m² fabric is tailored for projects requiring exceptional torsional stiffness and multidirectional strength, making it a go-to material for structural reinforcement and composite lamination.

Features

- High-Strength Construction: Made from premium-grade carbon fiber, this fabric offers excellent resistance to tension and compression forces, making it ideal for demanding structural applications.

- ±45° Orientation: The fabric’s unique weave pattern ensures balanced strength in multiple directions, enhancing load-bearing capacity and improving stability in parts exposed to shear stress.

- Lightweight & High Stiffness: Weighing in at 400 grams per square meter, this fabric provides an optimal balance of lightweight performance and stiffness, perfect for automotive, aerospace, marine, and sports equipment manufacturing.

- Easy to Handle and Apply: Suitable for wet-layup, infusion, and pre-preg applications, this fabric conforms well to complex shapes and contours, simplifying your composite layup process.

Applications

- Aerospace Components: Reinforcing fuselage, wings, and interior panels for weight reduction and enhanced durability.

- Automotive: Strengthening structural parts such as body panels, spoilers, and frames for performance and lightweight efficiency.

- Marine Industry: Hull reinforcement, decking, and other load-bearing parts in boats and yachts.

- Sporting Goods: Used in high-performance equipment like bicycle frames, fishing rods, skis, and snowboards.

- Wind Energy: Reinforcing wind turbine blades to handle high stress and fatigue over extended use.

- Construction and Architecture: Strengthening beams, columns, and other structural elements in buildings, bridges, and infrastructure projects.

- Industrial Equipment: Reinforcing robotics arms, machinery parts, and other heavy-duty industrial components.

- Medical Devices: Creating lightweight, durable structures for prosthetics, braces, and mobility aids.

- Renewable Energy: Reinforcement in solar panel frameworks and support structures for enhanced durability and lifespan.

- Electronics Enclosures: High-performance cases for drones, UAVs, and other sensitive electronics requiring impact resistance.

- Recreational Vehicles (RVs): Structural support for panels and lightweight furniture components to improve stability and reduce weight.

This fabric is versatile, making it suitable for any application where high strength, low weight, and reliability are key.

Properties

| Weave | +/- 45 Biaxial |

| Density / Area Weight | 400 g/m2 |

| Width | 1270 mm |

| Thickness | 0.38 mm |

| Laminate thickness | 0.43 mm |

| Resin Compatibility | Epoxy resin Polyester resin Vinylester resin Urethane resin |

| Resin consumption | Hand lay-up: ~410 g/m2 Vacuum bagging: ~330 g/m2 Vacuum infusion: ~220 g/m2 |