Crestamould® RTR 4010PA is an accelerated thixotropic polyester resin specially developed for rapid hand forming and lamination of composite or glass fibre shapes.

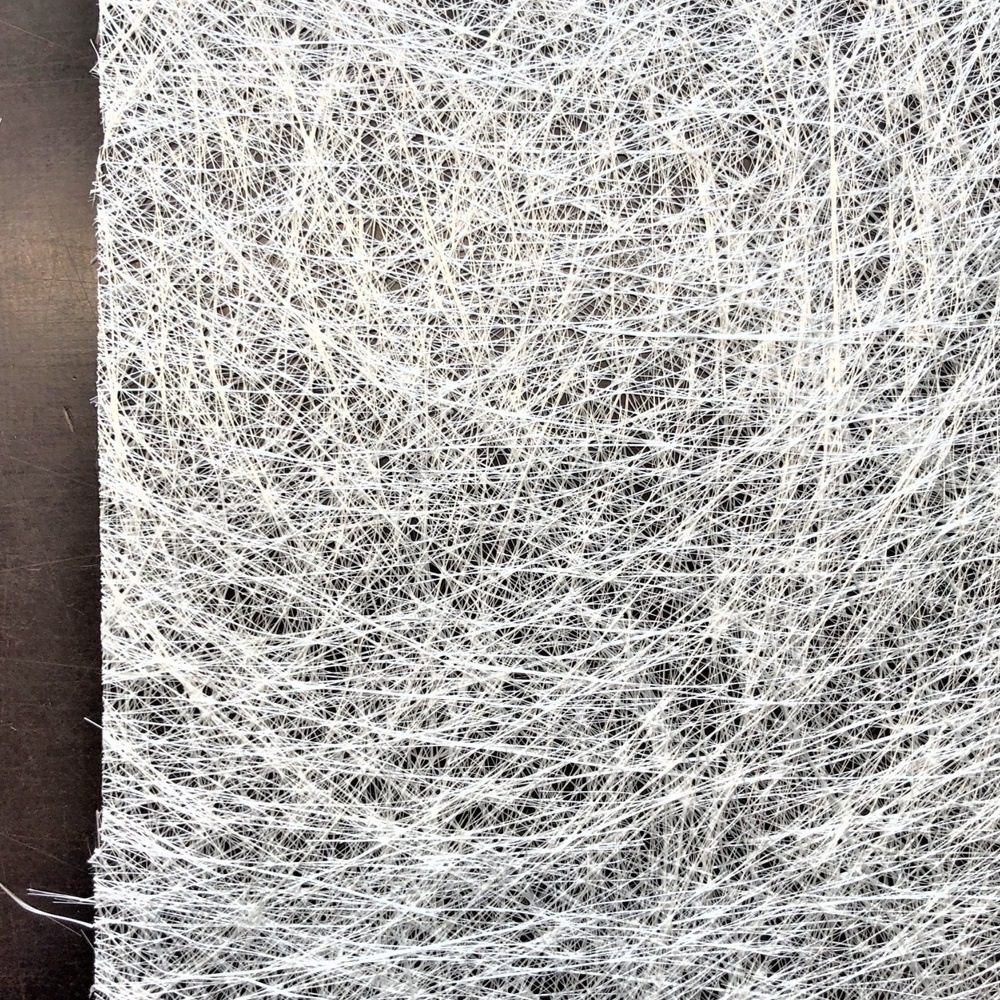

Crestamould® RTR 4010PA is a low viscosity resin with no shrinkage or shrinkage (0%). The resin can be used to form thick laminates – all the intended layers of glass fibre can be laminated at once. The laminate must consist of at least four layers of 450 g/m2 glass fibre mat for the resin to start the curing reaction.

The price includes the required quantity of Butanox M50 hardener.

To produce an optimal or technologically correct mould, you need:

- Crestamould® 15PA

Apply Crestamould® 15PA Shaped Gelcoat to the waxed surface. - Crestamould® 679PA + 1 layer 150 g/m2 fibreglass mat

After 2-8 hours – apply 1 coat of Crestamould® 679PA vinyl ester resin and 1 coat of 150 g/m2 glass fibre hair.

When laminating, it is preferable to press it against the gelcoat and squeeze out the bubbles with a bubble squeezing roller. - Crestamould® 4010PA + 4 coats 450 g/m2 fibreglass mat

After 8-16 hours, apply one coat of 450 g/m2 glass fibre hair, laminating with Crestamould® 4010PA to form a 4-layer laminate.

The resin application time is ~30 minutes and all 4 coats must be applied within this time.

Approximate quantity of materials needed to make the shape:

| Materials | 1 m2 | 5 m2 |

| Crestamould® 15PA gelcoat moulds | 1 kg | 5 kg |

| Glass fibre mat 150 g/m2 | 1 m2 | 5 m2 |

| Crestamould® 679PA vinylester resin | 0.5 kg | 2.5 kg |

| Glass fibre mat 450 g/m2 | 4 m2 | 20 m2 |

| Crestamould® 4010PA moulding resin | 5 kg | 25 kg |